Over the past few years, our customers have come to us with consistent challenges surrounding their metrology equipment used for precision surface measurement. Off-the-shelf metrology tool limitations forced them to look elsewhere. Not enough precision, not enough automation, and not the right measurement technology were all reasons that pushed to find alternatives. When their processes lacked precision automation they ended up working with custom tool builders or tried to build automated equipment themselves.

Although many of these customers have a long history of success working with motion control and automation equipment, such as our deep catalog of products, they still struggle to implement a complete solution that combines the other components that make up a metrology tool. The real burden on them is to overlap the automation control equipment with the measurement technology and supporting user interface software to round out the complete solution. They are not experts at building this equipment, and too many of their internal resources are sunk into these projects. Our metrology capital equipment team was born to help remove these burdens from customers so that they can focus on what makes them different from their competitors rather than the metrology processes that were holding them back. We help them reallocate their internal resources so that they are better positioned to make advancements core to their own company’s success. Leaving the design and manufacturing of the metrology equipment that solves their process up to us.

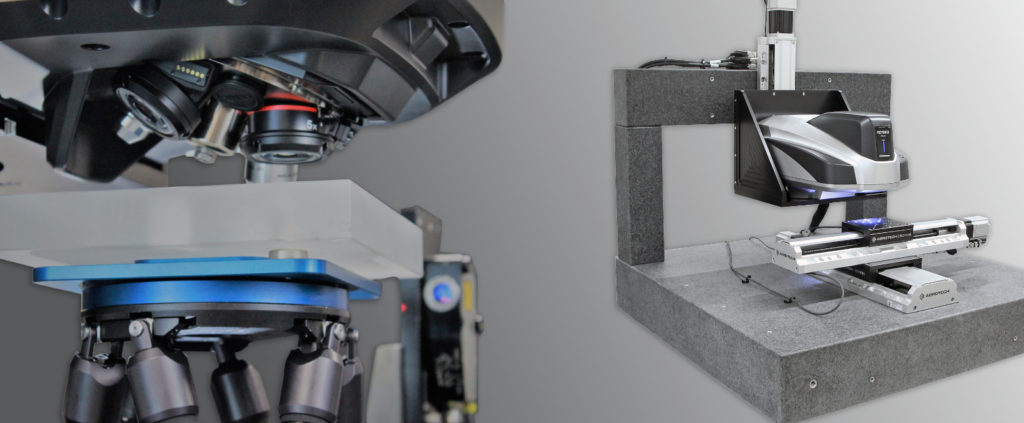

We have made significant developments in automating surface metrology processes through the use of industrial automation control systems and market proven sensing technologies. Because of our history in precision motion control and high-speed triggering of external devices we are uniquely suited to integrate a variety of sensors with automation hardware that meets our customer’s volumetric accuracy requirements. We have also developed multiple software user interfaces that allows us to pair large format motion systems with super-fine resolution microscopes, optical profilers, and a large variety of other precision sensors. We have abstracted the measurement technology from the fundamental requirement of triggering the device to take a measurement at a known position in space to give our customers a sensor-agnostic starting point to solve their surface measurement challenges. With this, a part of any size, shape, and material can be measured with the perfect sensor for the job.

Now that off-the-shelf measurement technologies and in-house engineering expertise are no longer burdening our customers they are free to focus on what matters most to their companies. Furthermore, they can now gather more meaningful measurement data of their parts in order to make better informed decisions that positively impact their customers and markets.