Advanced Features for VK Microscopes

Additional capabilities for your off-the-shelf VK microscope

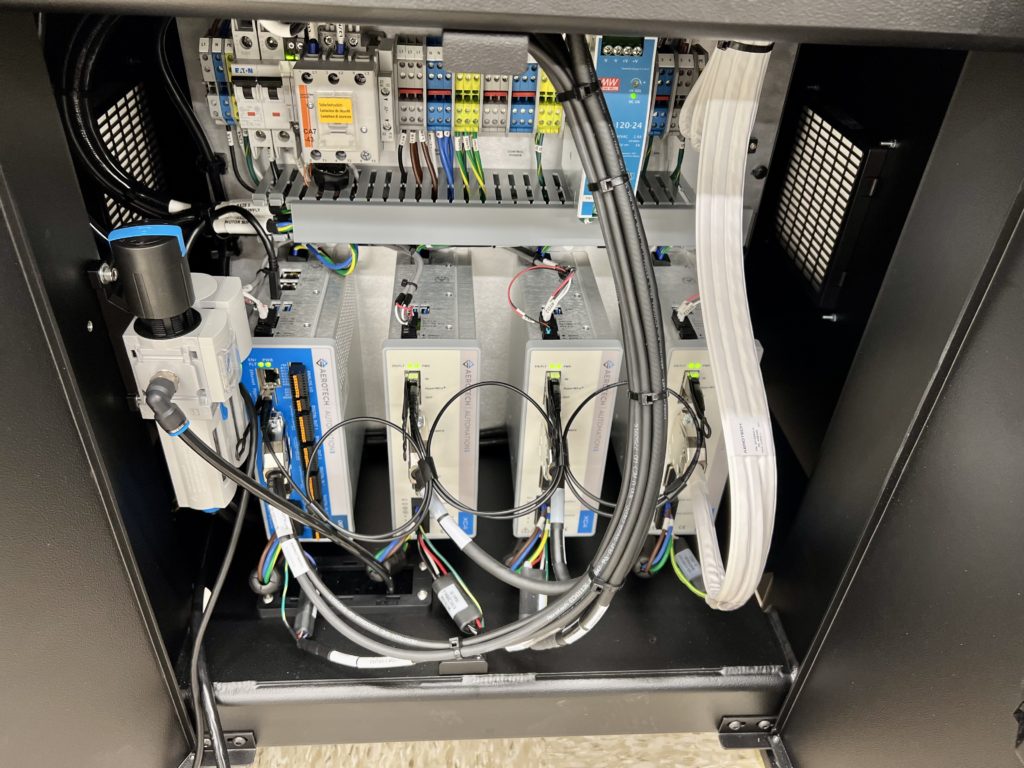

We offer a dedicated motion controller and software application that enables additional features in tandem with the VK microscope. This software application uses the Keyence VK programming libraries along with an advanced motion controller feature set. The user works out of this additional software application.

Check out the brochure and catalog →

Enabling automation features

We provide a software user interface that enables the use of advanced motion controllers, additional height sensors, rotary stages and other tools. This software provides the means to further automate the microscope, improve measurement throughput, and assists the operators in daily tasks.

3 reasons you would need our advanced controller and software

#1

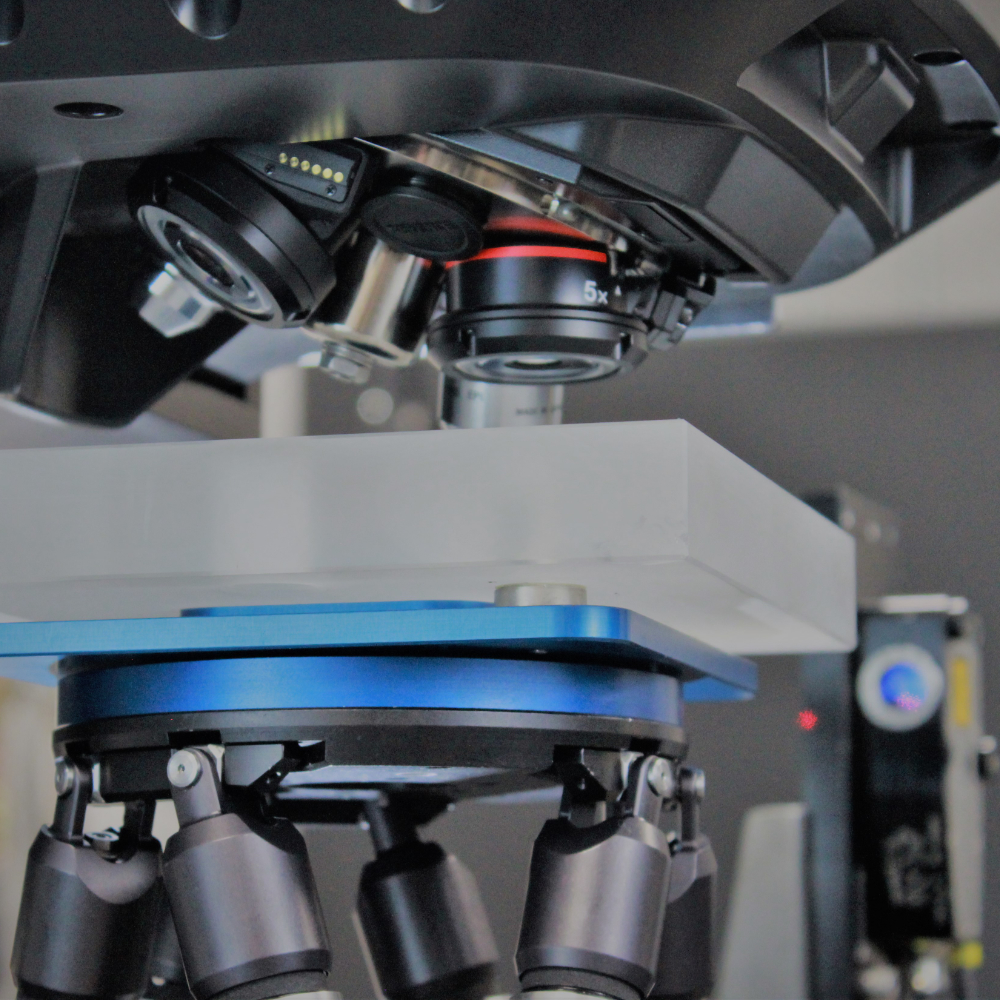

Rotary stage motion is required

Programming your measurement routine with a rotation stage often simplifies data acquisition.

Main benefits

Easier programming, faster data acquisition times, smaller machine footprints.

#2

Additional height sensors are needed

Large height variation across a sample surface (> 250 microns) restricts lens focus abilities.

Main benefits

Faster data acquisition times (often by a factor of 2 or more), lens collision avoidance, autonomous focus finding.

#3

Very large stage motion

Sample size (>800mm) and/or payload weight (>50kg) requires the use of larger stages.

Main benefits

Fit and measure many more unique part shapes, measure your heaviest parts.

#1 - Rotary motion

Rotary motion is helpful in many applications where programming in a rotationally symmetric space would streamline the data acquisition process.

- Orient your part perpendicular to the microscope for easy jogging

- Teach rotary stage position as part of a teach routine

- Use rotary motion as part of a fiducial alignment process

A full report of rotary stages being used for alignment can be found here.

Video Overview

Rotary stages in automated teach routines

Video Overview

Rotary stages for part alignment processes

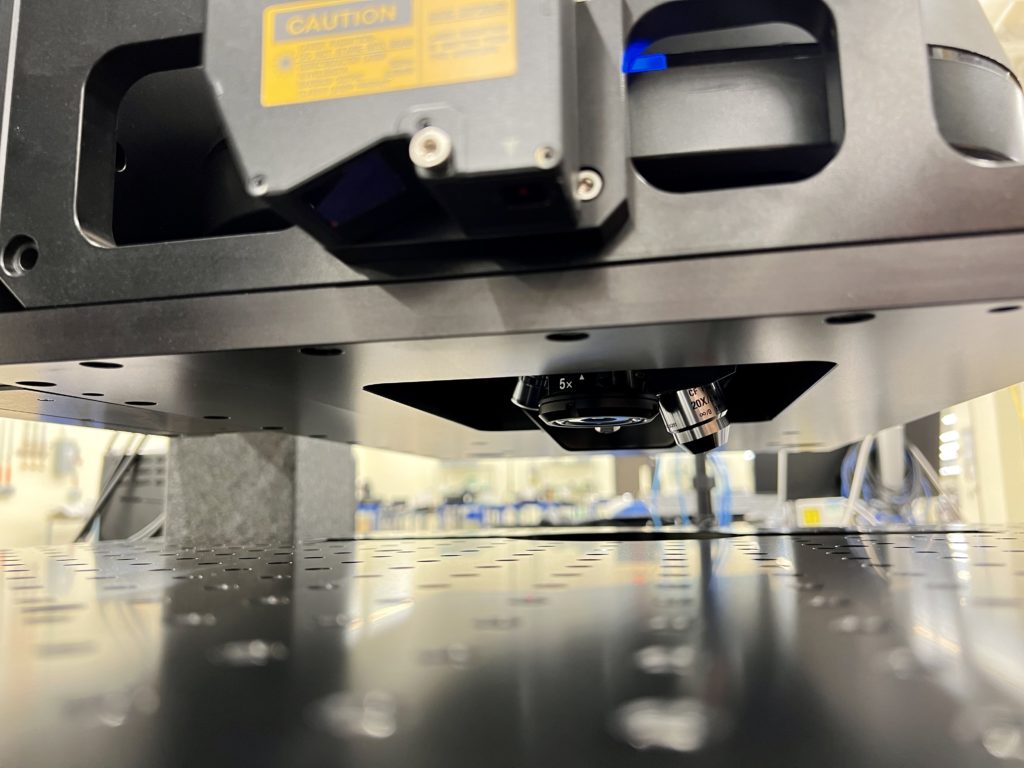

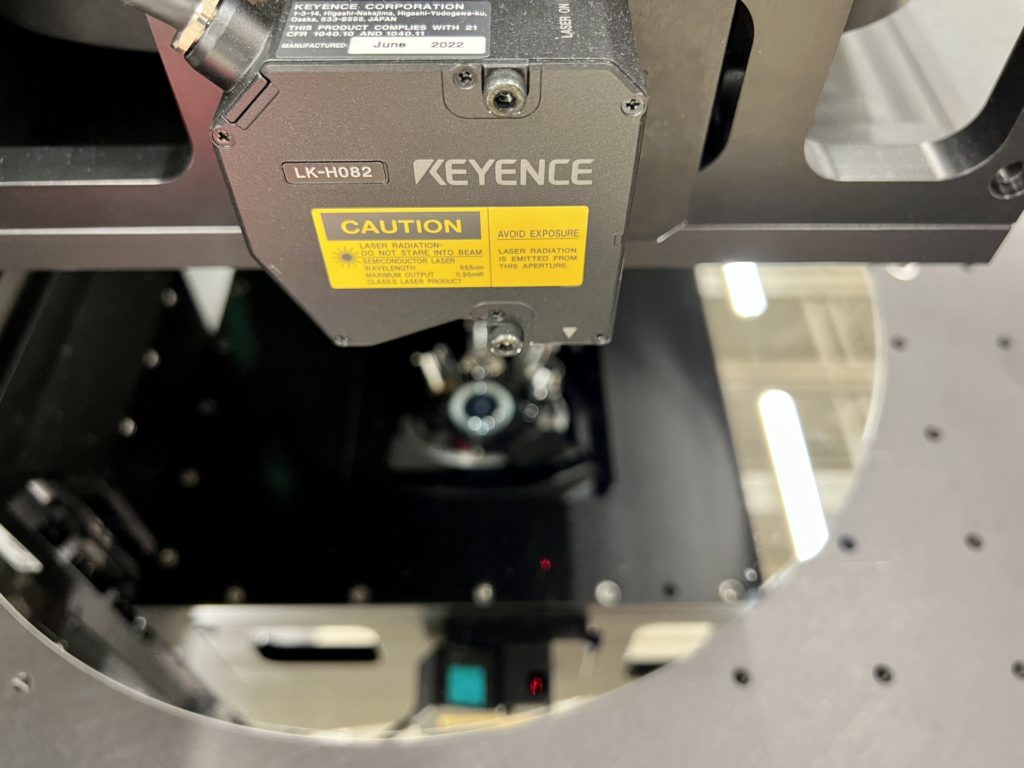

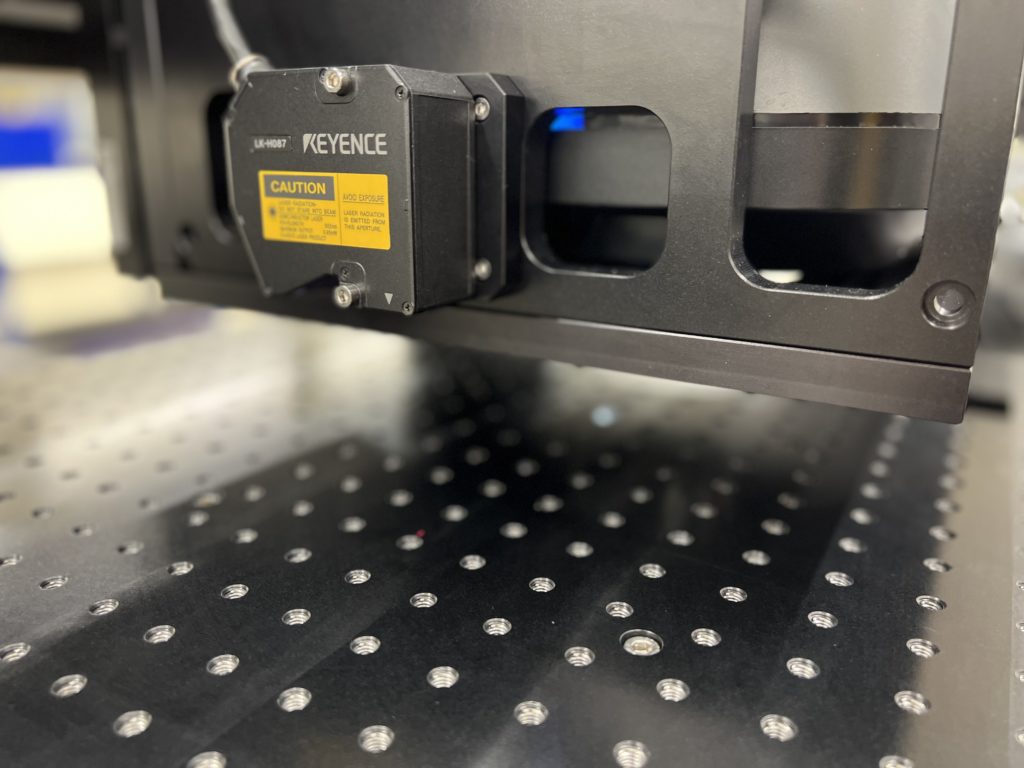

#2 - Height sensors

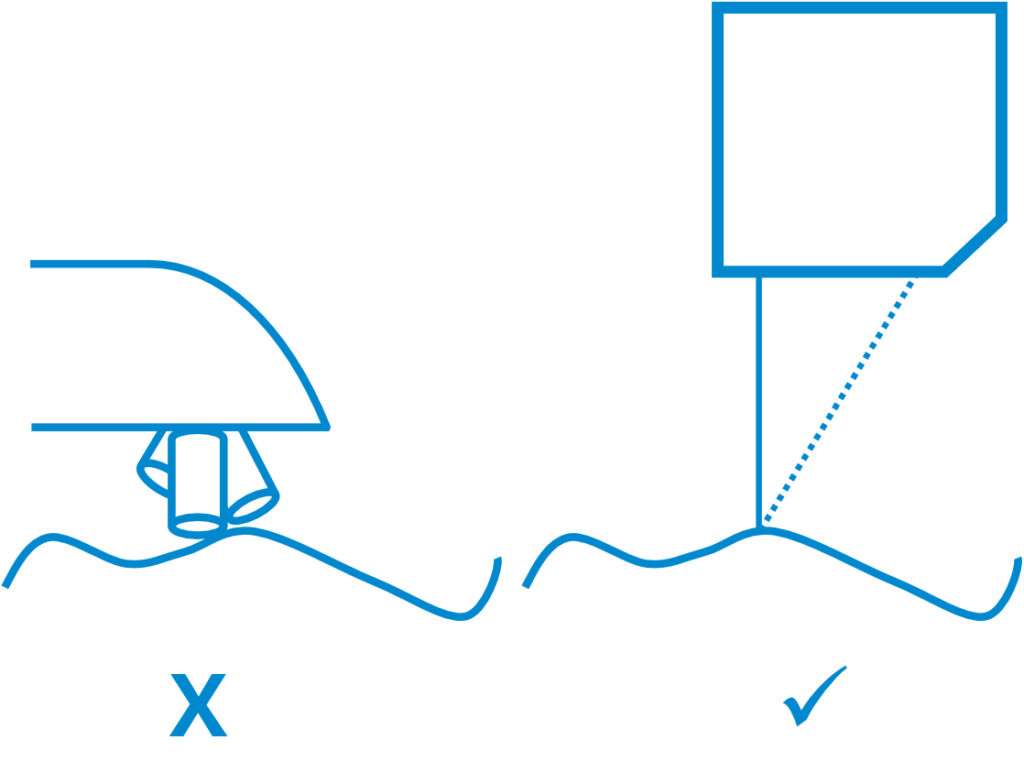

If the surface you are measuring has heights that fall outside of the VK’s focus capabilities you will experience difficulty in automating the focal adjustment of the microscope. In addition, this may lead to collisions between the objective lens and sample surface often causing expensive damage.

Our solution:

- A larger travel vertical stage is used to adjust for surface height variations

- A height sensor is added to measure these height variations

- Our software takes these measured variations and compensates for them using the vertical stage

An article describing the technical details about this approach can be found here:

Video

Height sensor overview

Image gallery

Video

Height sensor demo

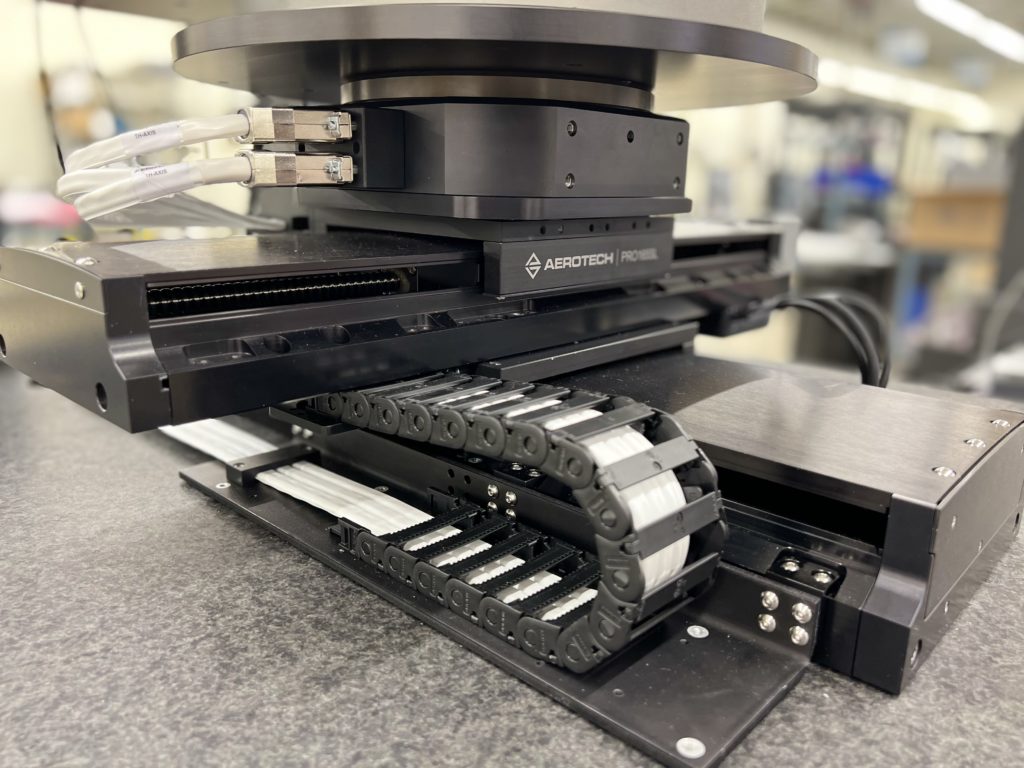

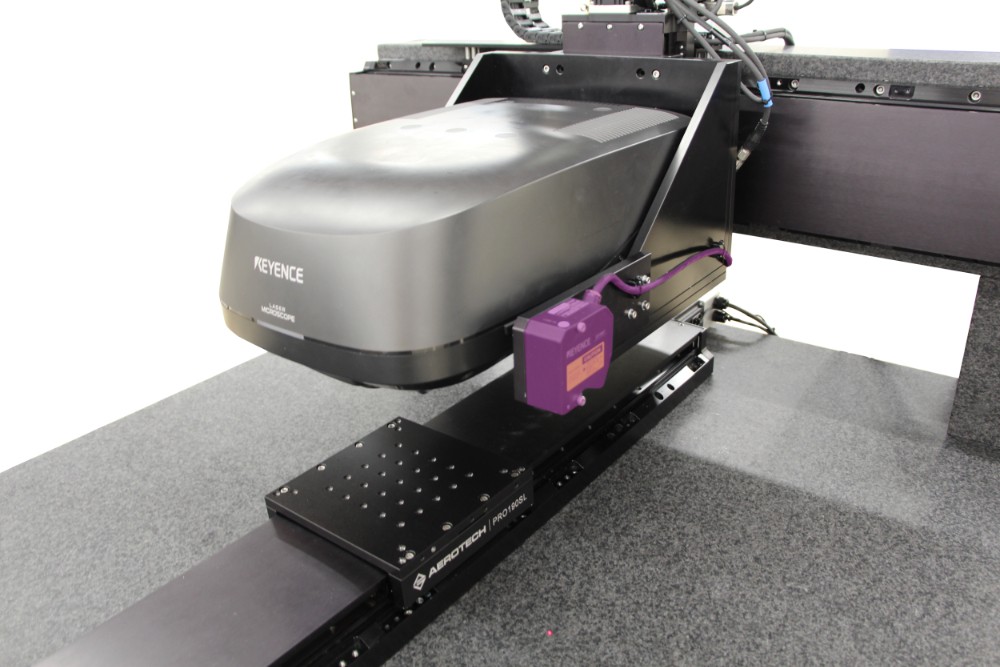

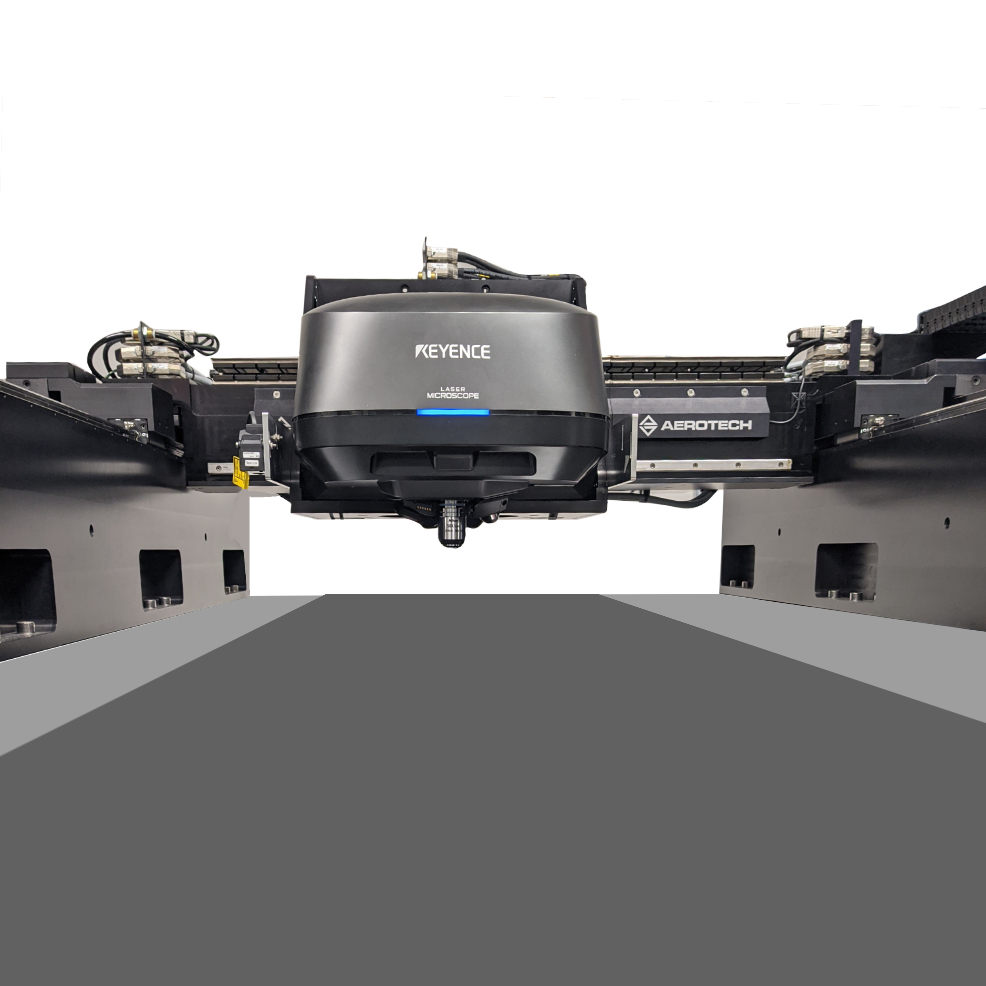

#3 - Larger or unique stage motion

If your sample surface is large or complex, we can purpose build a unique motion system to move the sample or the microscope head. For example, long parts, flat sheets, or heavy objects are best suited for our purpose built machines.

Our solution:

- Utilize the catalog of Aerotech stage products to best fit the application

- Our Systems Engineering team will design and document the equipment needed

- Your part characteristics dictates whether we move the sample or the microscope head itself

An article describing the technical details about this approach can be found here:

Video

2+ meter travel of motorized positioning

Video

800mm x 800mm x 200mm travel of motorized positioning

What does the advanced controller and software look like?

Motion controller for advanced equipment control

Additional software for power microscope users

Additional Resources

Educational articles, white papers, and videos to help you make more informed decisions about your equipment purchases.

Help files, CAD downloads, and installation videos. Get in touch with your peak representative for the password.

Advanced Products

Enabling automation features

We provide a software user interface that enables the use of advanced motion controllers, additional height sensors, rotary stages and other tools. This software provides the means to further automate the microscope, improve measurement throughput, and assists the operators in daily tasks.