Sensor Scanning Equipment

Explore the range of equipment we build for our customers

Choose the equipment that works best for your project.

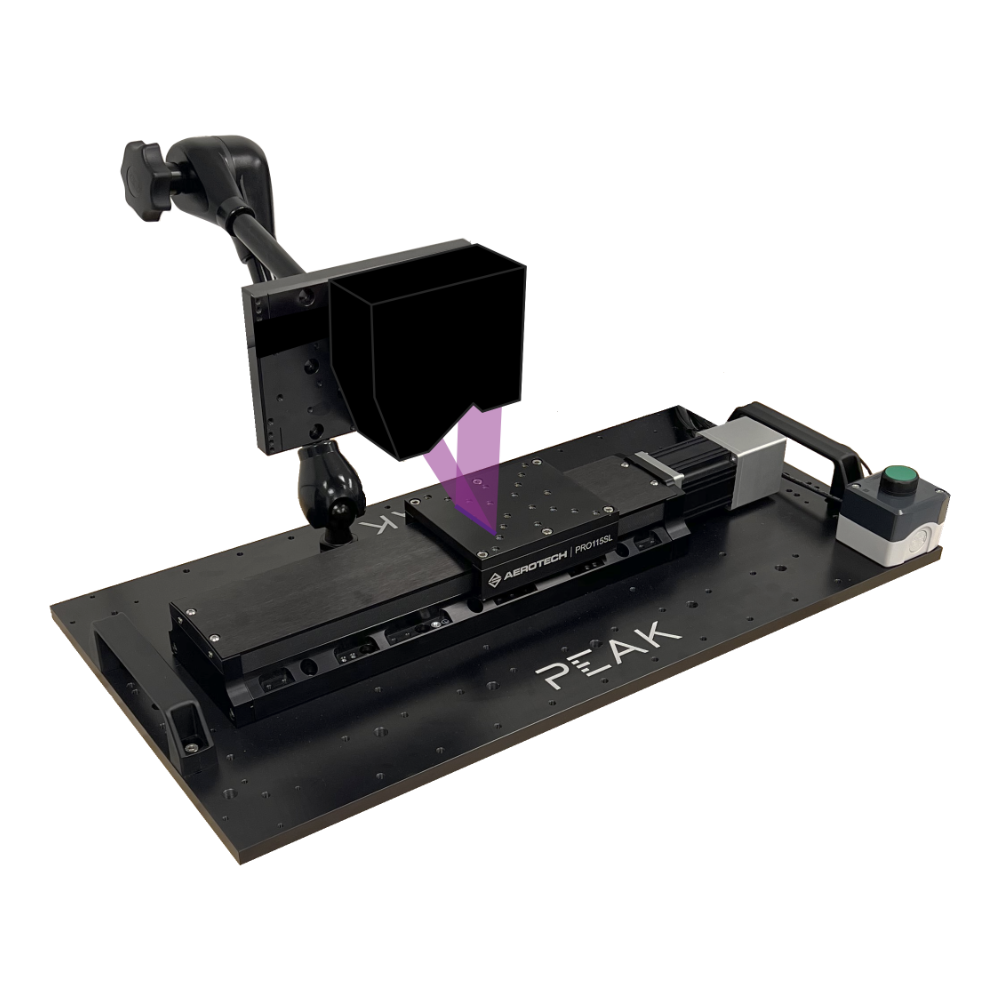

Benchtop scanning solutions

1, 2, or 3 axis motorized positioning stages for automated part scanning. Ideal for laboratory and small batch production environments.

Standalone surface measurement tools

Programmable tools for profilometry and thickness measurement. Supports linear and rotary part motion and multiple sensors.

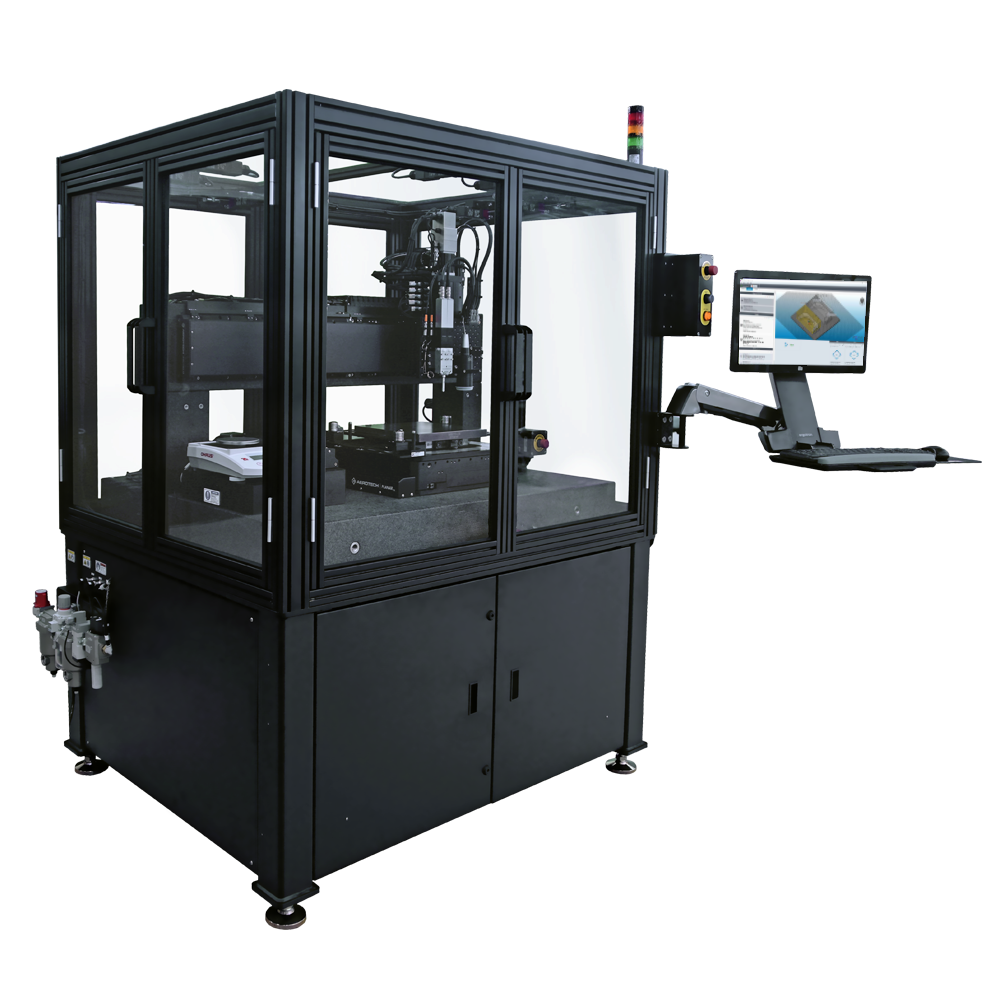

Automated measurement machinery

Incorporate our core measurement tools inside of a factory automated machine. Ideal for fully autonomous operation and production settings.

We build automation equipment for surface profiling and analysis

Application examples

Measurement solutions

Export your raw surface measurement data for in-house analysis or use our Surface Analysis Imaging Topography software to calculate critical parameters and dimensions.

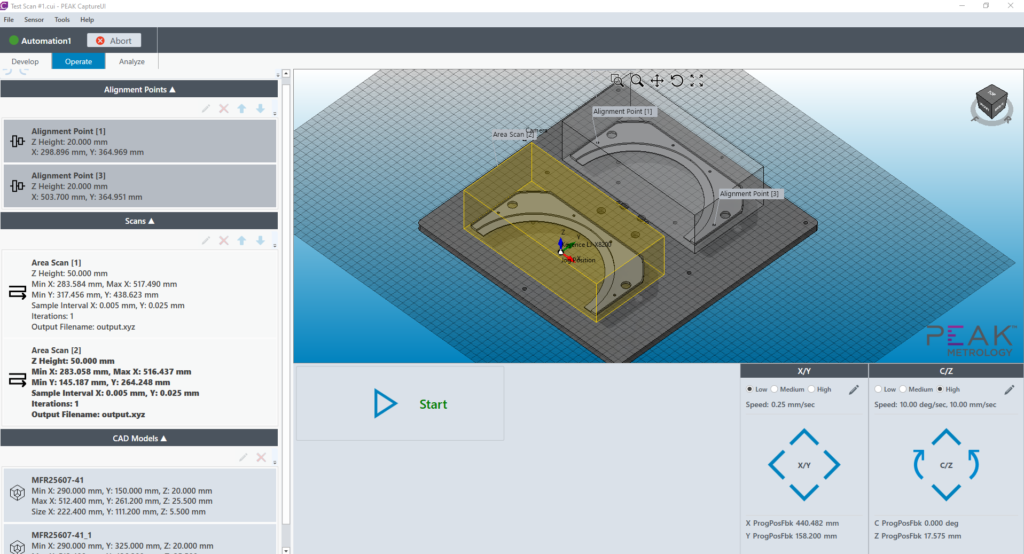

Software to put you in the driver's seat

Create scan programs

CaptureUI is a software application that enables automated scan control. At its core, CaptureUI brings sensor data acquisition and precision motion control together so that you don’t have to. The tools provided in this interface allow you to create and execute scans to match your process needs.

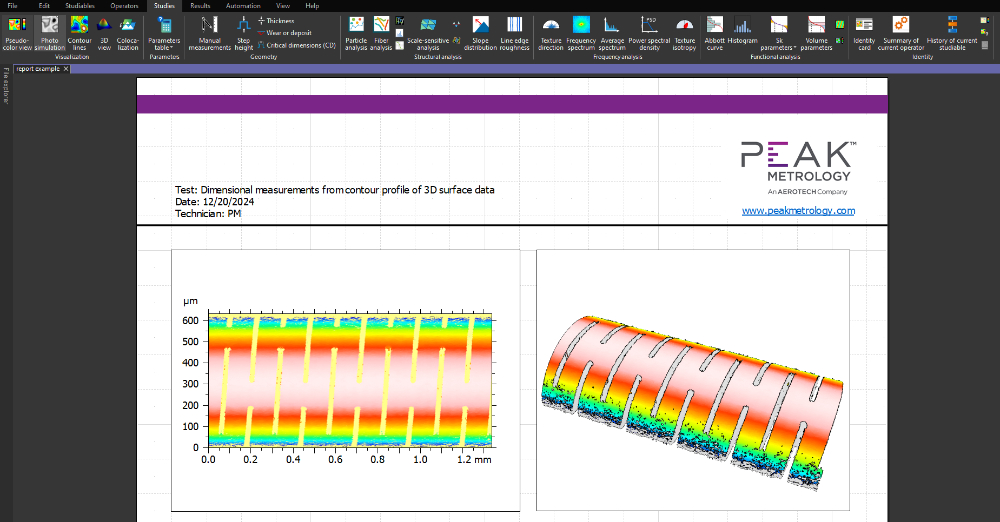

Analyze datasets

Our Surface Analysis Imaging Topography software is used to analyze instrument data. Templates can be created and applied automatically through our CaptureUI machine interface.

- Modify datasets to prepare them for analysis

- Apply tools and templates to create measurement results

- Export the results in a way that is meaningful to your needs

Automate your measurement process

We automate scanning through measurement data export.

We also offer industrial protocols to connect to almost any factory automation system for material handling and/or measurement result publication to a database.

- Industrial protocols (EthernetTCP/IP, EtherCAT, and others)

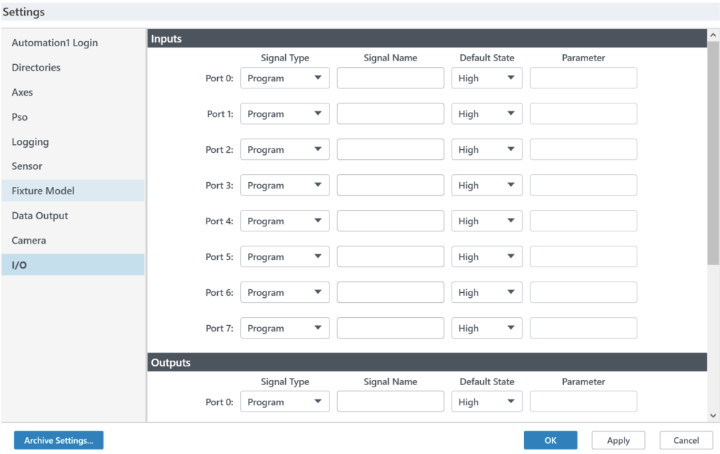

- Hardwired IO and signal handshaking

- Local or networked database management

See it in action

Watch our equipment run through a measurement recipe.

- Switch between sensors in the same program

- Use additional part handling to reposition parts automatically

- View the results in our Peak Surface Analysis software

We integrate a wide range of measurement devices

Point Sensors

Laser, interferometric, and chromatic confocal point sensors. Ideal excellent accuracy and vertical resolution.

Line Sensors

Laser and confocal line profile sensors. These are ideal for high density data collection.

Area Sensors

White light interferometry and fringe projection area sensors. These work well when fast measurement times are desired.

Vision Systems

Vision systems and cameras. Implemented for fiducial recognition, defect detection, and alignment processes.

Our expertise in action

Unmatched Precision

We are experts at precision engineering. Maintaining measurement accuracy over larger or more complicated surfaces is our specialty.

High Data Density

We excel at scanning surfaces while collecting high density datasets. Single micrometer pixel sizes is a realm we lean into.

Data Stitching

Moving sensors and surfaces to create larger datasets is a core competency of our equipment and software.