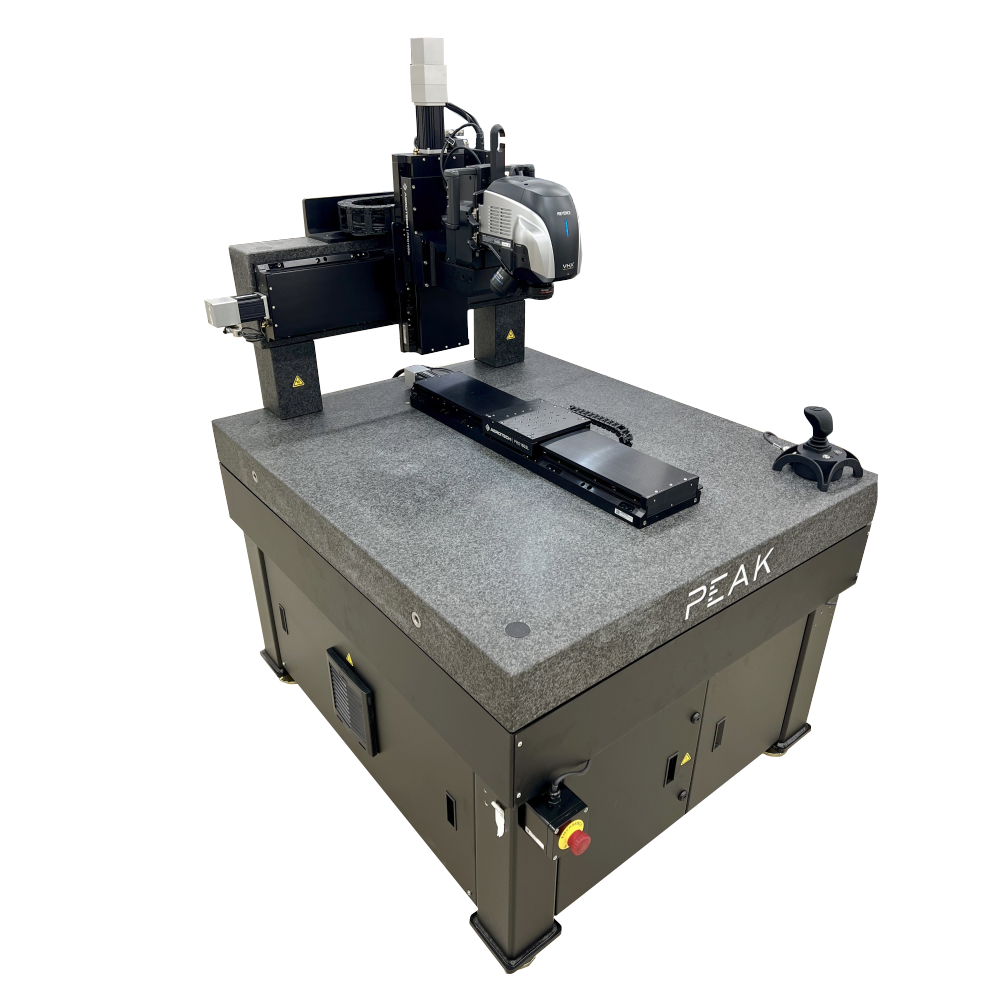

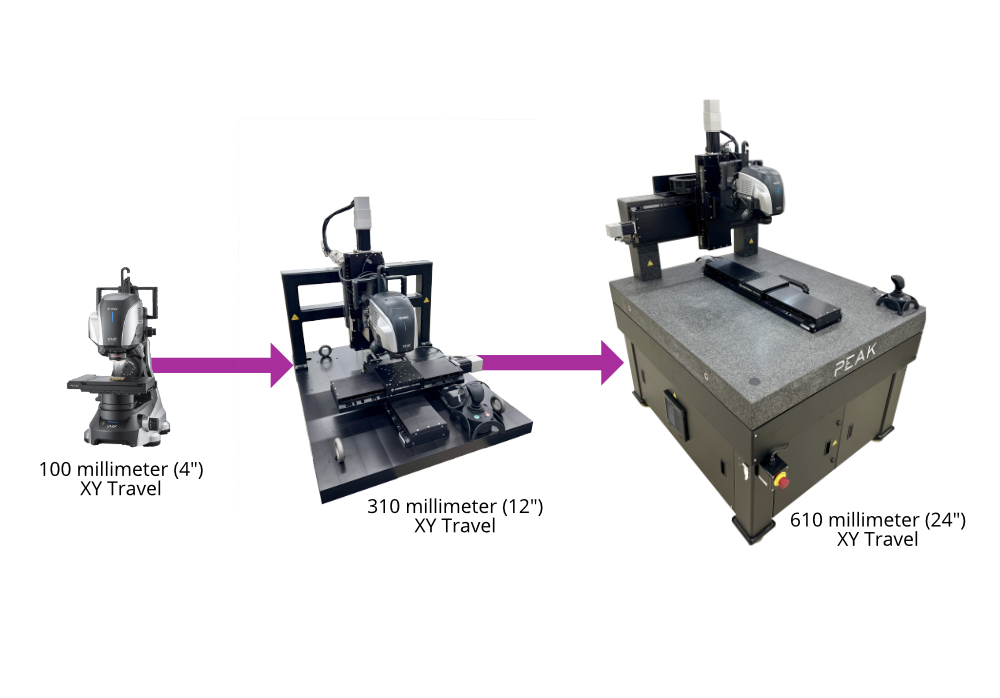

Larger positioning Systems for VHX Microscopes

Large format Stages

Image larger Surfaces

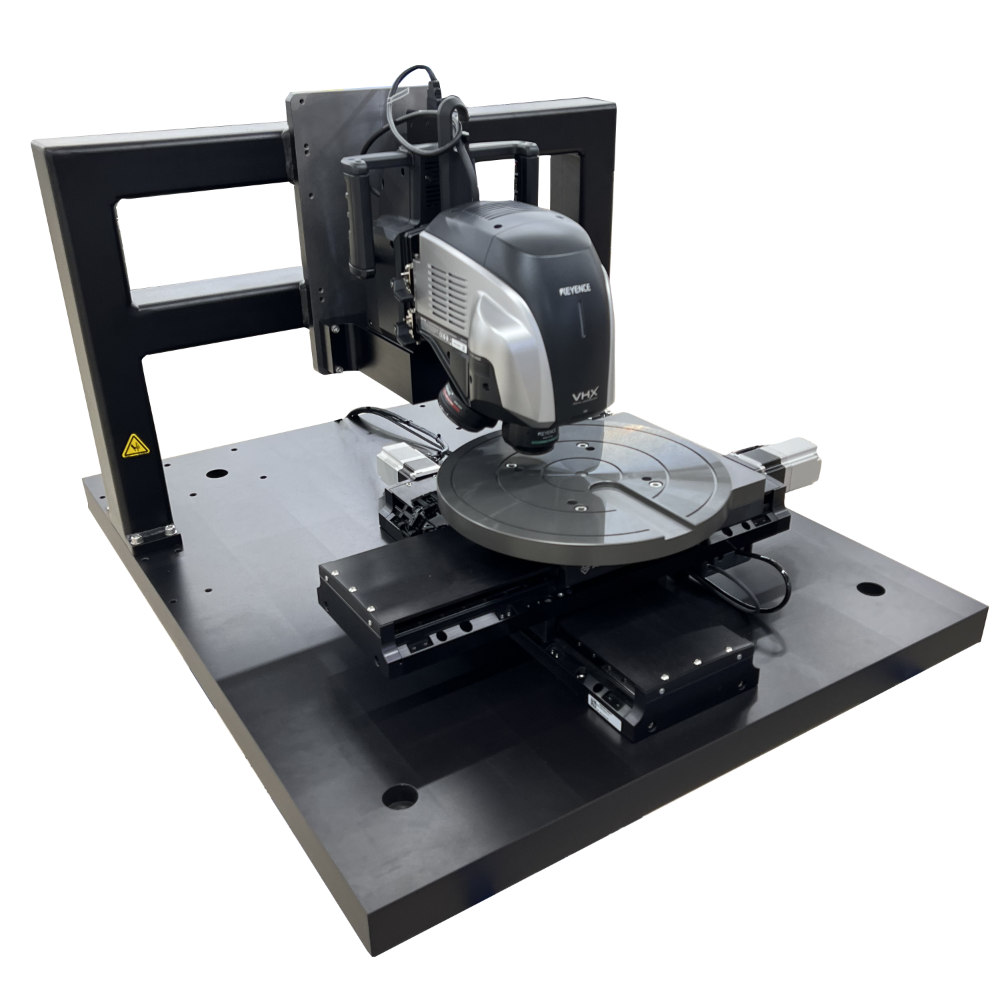

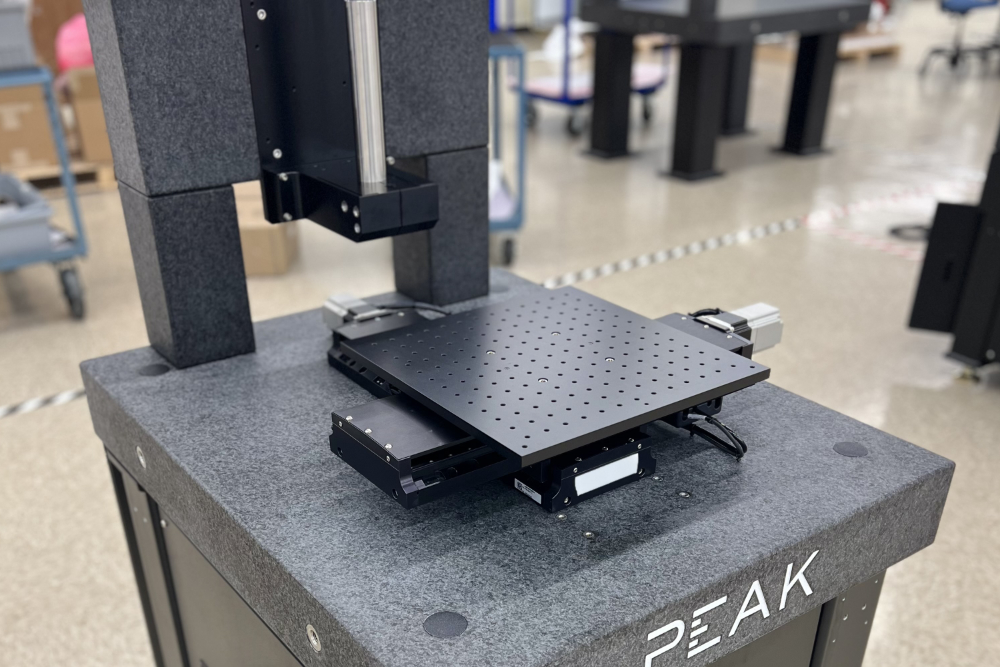

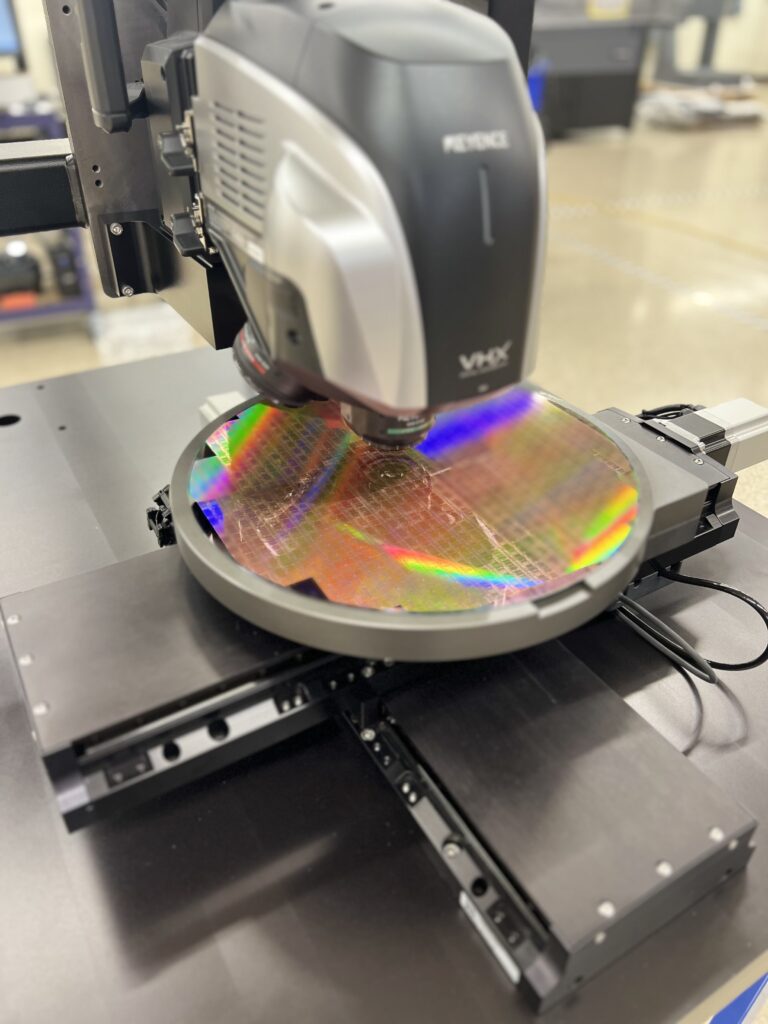

These motorized stages increase the working volume and payload capacity of the VHX microscope from Keyence. They are ideal for microscope users that need to image over larger surfaces or bigger trays of smaller parts.

Have questions? Contact an expert.

How it works

Motorized Stages and Automation

These stages are designed and built to be easily integrated with the Keyence VHX microscope. The microscope head mounts directly to our product and setup is streamlined. We offer installation and training services to make it even easier.

- Run the stages natively from standard Keyence software

- Add Peak software to get even more automation features

- Quick ship and custom options are available

There are two methods to control the motorized stages.

Option #1

Standard Keyence Software

Use the Keyence software and console to control the XY stages.

Available for the VHX-7000N and newer microscope models. Only a few features of the 7000 software are unavailable with the Peak stage:

- Focus view camera is unavailable

- Tilt axis is unavailable (and eucentric adjustment)

- FI head collision prevention

- One push calibration

Standard VHX-7000 user software. No additional software needed.

Keyence supplied VK-S1000K stepper motor controller. Peak Metrology supplied stage cable.

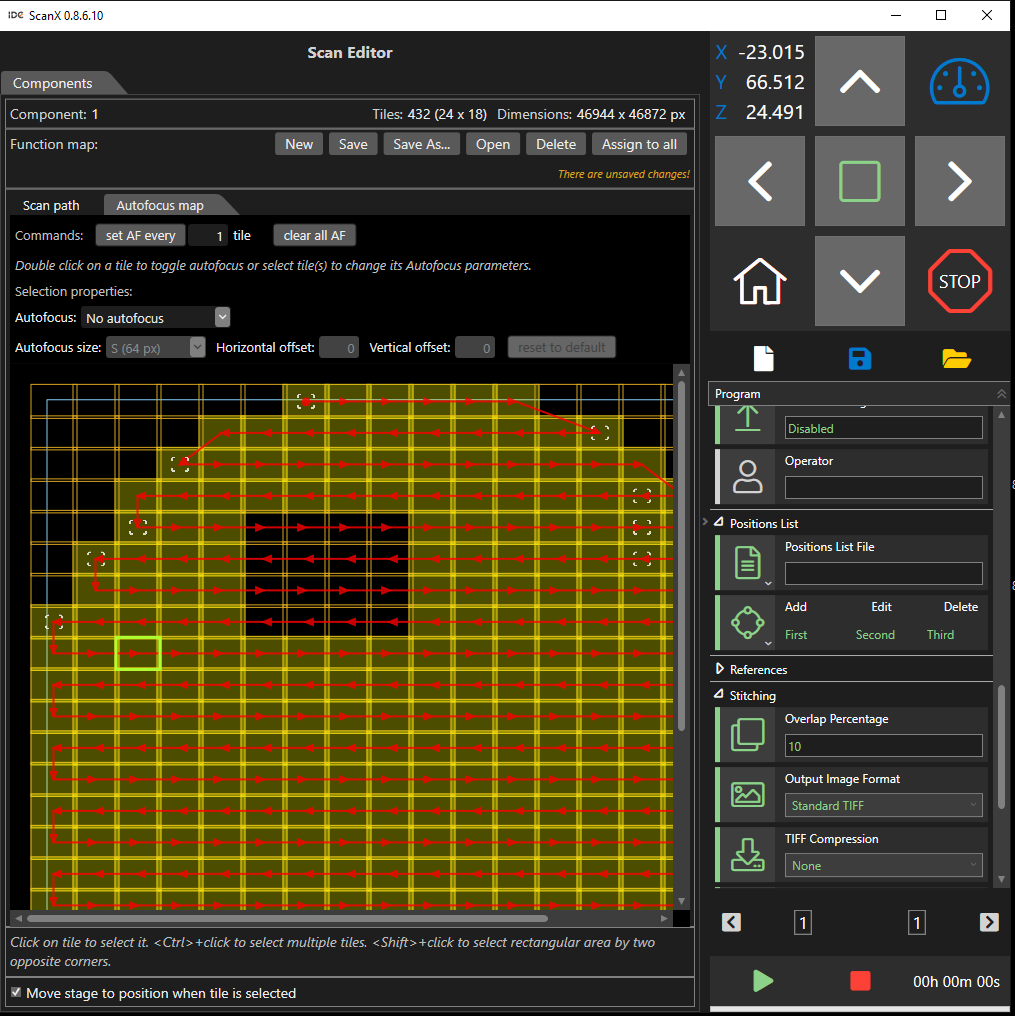

Option #2

Additional Automation Software

Use an additional layer of software to automate image acquisition.

Available for VHX-6000 and newer microscopes. When using additional software such as ScanX the Keyence microscope is controlled in “remote” mode. Some Standard VHX features are no longer available in this mode. For a full list visit this page.

Feature List for Remote Software Control

Contact your Keyence representative to see if these are software functions that you need.

Standard VHX-7000 user software.

Additional ScanX stage control and image acquisition software. This software controls the VHX microscope through the remote interface. The software can be disconnected from the microscope when desired.

Peak Metrology supplied motion controller for servo motor stages. This controller provides greater positioning accuracy and control over the XY stages.

Product Catalog

Large Travel Stages for VHX Microscopes

Our catalog covers many of the options that we provide to our customers. It includes:

- Product specifications and dimensions

- Standard ordering options and configurations

- A list of items required from Keyence for integration

Product Option

Vibration Isolation Systems

We have extensive experience controlling floor vibrations of all levels. We will help you maintain the performance of your microscope regardless of your environment.

Showing image shake at a 2500x magnification. This video was recorded without the use of a vibration isolation system to remove the image shake.

Product Option

Part Holding Fixtures and Vacuum Chucks

Breadboard Fixture Plates

Anodized aluminum plates with a breadboard hole pattern.

Porous Vacuum Chucks

Porous ceramic vacuum chucks. Square and round shapes available.

Multi-Zone Vacuum Chucks

Hard coated and ground aluminum vacuum chucks. Multi-zone selectable vacuum pattern. Cutouts for wafer placement and removal.

Custom Tooling and Fixtures

Use our engineering team to design a purpose-built fixturing solution.

Product Option

Tilt Stages

We offer tilt stages to adjust the viewing angle of your microscope. These tilt stages are motorized or manually operated, and have travels up to +/-90 degrees.

Showing the manual tilt stage option.

Showing the motorized tilt stage option.

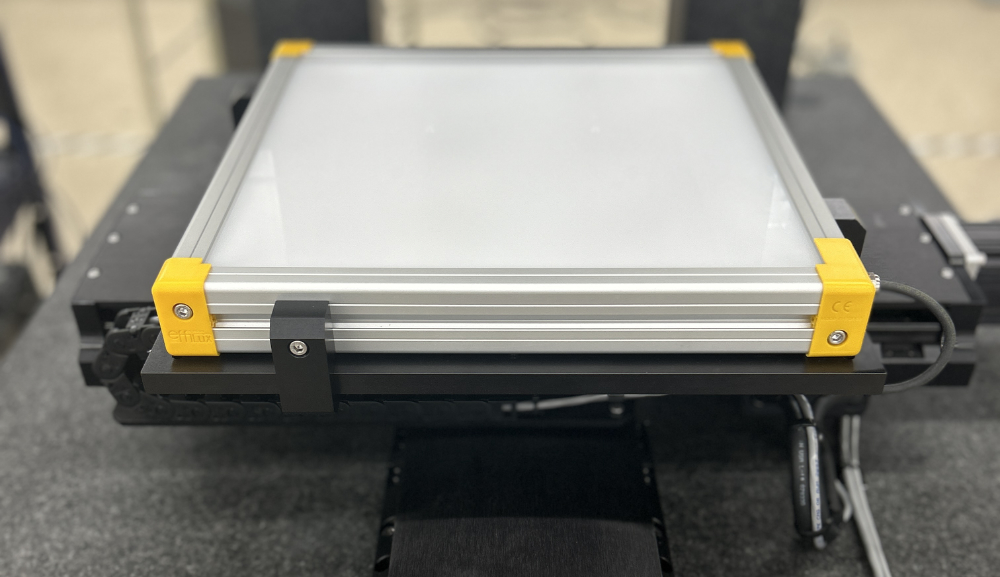

Showing an adjustable brightness LED backlight.

Video showing backlight in operation.

Product Option

Backlights

We offer backlights of various sizes to illuminate transparent or semi-transparent surfaces.

Mounting of the microscope and sample part

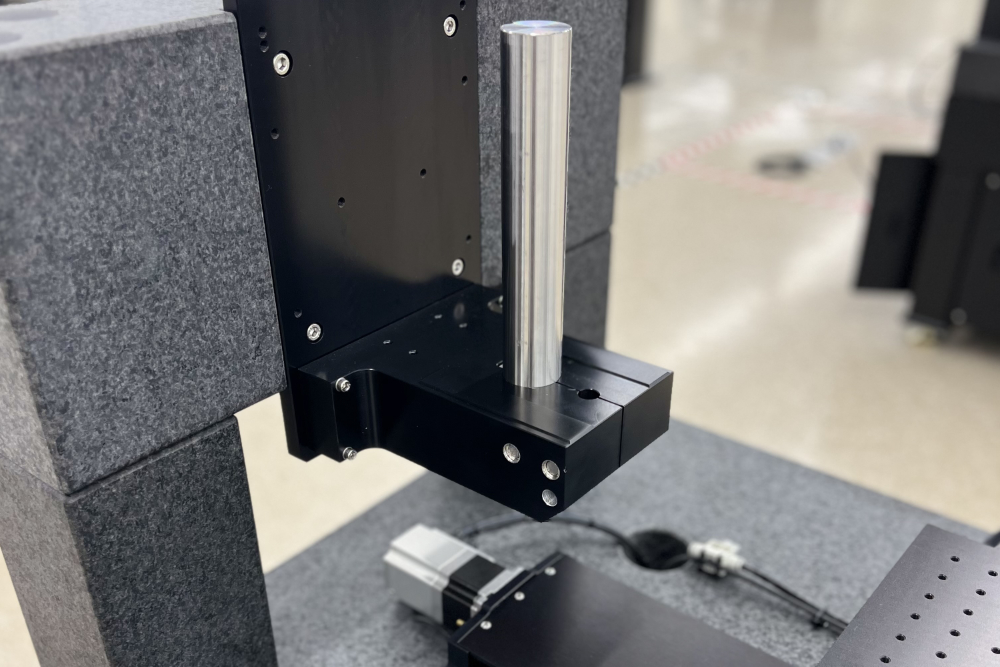

Step 1

Slide the Keyence Z stage onto the post that is provided by Peak Metrology. The post is pre-aligned and includes a self centering groove for microscope alignment.

Step 2

If ordered, we will provide a mounting plate for your part to be placed and/or attached. The plate will mount to one of the motorized stages. Ask us about the options we have to mount your specific parts and samples.

Advanced Products

Automation Software for VHX Microscopes

This product extends the functionalities of the off-the-shelf Keyence VHX software. This product combines programming libraries provided with the Keyence VHX alongside a programmable motion controller from Aerotech.

- Further automate the out-of-the-box Keyence microscope and software

- Uses an advanced motion controller to enhance machine programmability

- Most useful for customers looking to reduce labor required to run the tool

Choose the Features that Solve Your Application

TEACHING (Create Programs for Automation) | Keyence VHX Software | Additional Software (ScanX) |

|---|---|---|

Program XYZ teach points and save them as an program file | YES (1 file per user max) | YES |

Teach lens magnification at every point | YES | |

Import teach points from Excel / CSV table | YES | |

Teach single images AND stitched images | YES | |

Teach larger travel Z stage, tilt stage, and rotary stage positions | YES | |

Name image output files based on teach location | YES | |

Program autofocus settings as part of your teach file | YES | |

View your program on a "map" view | YES | |

Use patterns to create your teach program | YES |

Automated Stitching (Combining Single Images Together) | Keyence VHX Software | Additional Software (ScanX) |

|---|---|---|

2D Image Stitching | YES | YES |

3D Image Stitching | YES | |

Max Image Size | 50k x 50k pixels | Unlimited |

Operator Functions | Keyence VHX Software | Additional Software (ScanX) |

|---|---|---|

Single user interface software | YES | |

Navigation function

| YES

| YES (through MAP) |

Part alignment (fiducial registration for teach program) | YES | |

Part load / unload positions | YES |

Product Gallery

Examples of Our Work

Video Gallery

Examples of Our Work

Example applications for a larger stage

Semiconductor

The semiconductor and microelectronics industry is our #1 customer base.

Electronics

PCB’s and consumer electronic devices are often built in larger form factors ideal for our stages.

High value manufactured parts

Manufacturing in Aerospace, Defense, Automotive, Medical Device, and a variety of other industries.

Additional Resources

Help files, CAD downloads, and installation videos. Get in touch with your peak representative for the password.